Services: Cast House

Uniquely positioned…

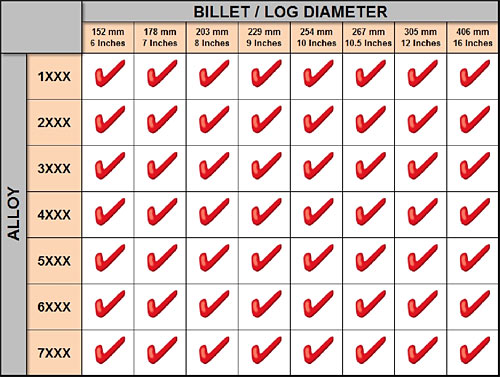

to provide high quality, specialty alloys in log and billet form. Capable of meeting minimum order quantities and in

short lead-times.

Signature Aluminum Canada Inc. produces a large selection of standard and specialized aluminum alloy billets and logs, which can be produced in various diameters and lengths upon request. Each billet is cast using state-of-the-art in-line degassing, filtration, and mold technology. Alloy chemistry is tailored to offer our customers the best combination of extrudability, surface finish, and mechanical properties; all attributes which carry through to the bottom line.

Specially developed homogenizing and cooling practices produce a starting stock that performs well under a wide range of preheating and extruding conditions. Quality extrusions obviously start with the highest quality aluminum alloys. Experienced and dedicated people, along with the most modern technologies, come together at Signature Aluminum to produce products of the highest quality. Signature Aluminum Canada, Inc.'s manufacturing process utilizes the latest in casting technologies:

• Ceramic foam filtration

• Novelis® Jet Cleaner™ aluminum degassing

• Wagstaff® Numax™ billet casting

If you're looking for a high quality source for your log and billet needs, look no further than Signature Aluminum Canada, Inc.

Aluminum Alloys

For your convenience we have included a series of specification tables for your reference:

CHEMICAL COMPOSITION LIMITS FOR WROUGHT ALUMINUM ALLOYS 1, 2

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | - | Others3 Each |

Others3 Total |

Alum. Min.4 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1100 | 0.95 Si+Fe |

- | 0.05-0.20 | 0.05 | - | - | - | 0.10 | - | - | - | - | 0.05 | 0.15 | 99.00 |

| 13507 | 0.10 | 0.40 | 0.05 | 0.01 | - | 0.01 | - | 0.05 | - | - | - | - | 0.038 | 0.10 | 99.50 |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | - | - | 0.10 | - | - | - | - | 0.05 | 0.15 | Remainder |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | - | - | - | - | 0.05 | 0.15 | Remainder |

| 6005 | 0.6-0.9 | 0.35 | 0.10 | 0.10 | 0.4-0.6 | 0.10 | - | 0.10 | 0.10 | - | - | - | 0.05 | 0.15 | Remainder |

| 6005A | 0.5-0.9 | 0.35 | 0.30 | 0.50 | 0.4-0.7 | 0.30 | - | 0.20 | 0.10 | - | - | 0.12-0.50 Mn+Cr |

0.05 | 0.15 | Remainder |

| 6060 | 0.3-0.6 | 0.10-0.30 | 0.10 | 0.10 | 0.35-0.6 | 0.05 | - | 0.15 | 0.10 | - | - | - | 0.05 | 0.15 | Remainder |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | - | 0.25 | 0.15 | - | - | - | 0.05 | 0.15 | Remainder |

| 6063 | 0.2-0.6 | 0.35 | 0.10 | 0.10 | 0.45-0.9 | 0.10 | - | 0.10 | 0.10 | - | - | - | 0.05 | 0.15 | Remainder |

| 6066 | 0.9-1.8 | 0.50 | 0.7-1.2 | 0.6-1.1 | 0.8-1.4 | 0.40 | - | 0.25 | 0.20 | - | - | - | 0.05 | 0.15 | Remainder |

| 6070 | 1.0-1.7 | 0.50 | 0.15-0.40 | 0.40-1.0 | 0.5-1.2 | 0.10 | - | 0.25 | 0.15 | - | - | - | 0.05 | 0.15 | Remainder |

| 6082 | 0.7-1.3 | 0.50 | 0.10 | 0.40-1.0 | 0.6-1.2 | 0.25 | - | 0.20 | 0.10 | - | - | - | 0.05 | 0.15 | Remainder |

| 61015 | 0.30-0.7 | 0.50 | 0.10 | 0.03 | 0.35-0.8 | 0.03 | - | 0.10 | - | - | - | - | 0.036 | 0.10 | Remainder |

| 6105 | 0.6-1.0 | 0.35 | 0.10 | 0.15 | 0.45-0.8 | 0.10 | - | 0.10 | 0.10 | - | - | - | 0.05 | 0.15 | Remainder |

| 6351 | 0.7-1.3 | 0.50 | 0.10 | 0.40-0.8 | 0.40-0.8 | - | - | 0.20 | 0.20 | - | - | - | 0.05 | 0.15 | Remainder |

| 6463 | 0.2-0.6 | 0.15 | 0.20 | 0.05 | 0.45-0.9 | - | - | 0.05 | - | - | 0.05 | 0.15 | Remainder | ||

| 7004 | 0.25 | 0.35 | 0.05 | 0.20-0.7 | 1.0-2.0 | 0.05 | - | 3.8-4.6 | 0.05 | - | - | 0.10-0.20 Zr |

0.05 | 0.15 | Remainder |

| 7005 | 0.35 | 0.40 | 0.10 | 0.20-0.7 | 1.0-1.8 | 0.06-0.20 | - | 4.0-5.0 | 0.01-0.06 | - | - | 0.08-0.20 Zr |

0.05 | 0.15 | Remainder |

| 7129 | 0.15 | 0.30 | 0.50-0.9 | 0.10 | 1.3-2.0 | 0.10 | - | 4.2-5.2 | 0.05 | - | - | - | 0.05 | 0.15 | Remainder |

A GUIDELINE FOR RELATIVE COMPARISON OF CHARACTERISTICS FOR SOME ALUMINUM ALLOYS

Contact Signature Aluminum for assistance in selecting the best alloy for your application.

| 6082 | 6061 | 6005 | 6105 | 6063 | 6060 | 6463 | 6101 | |

|---|---|---|---|---|---|---|---|---|

| Strength (tensile) | 10 | 9 | 8.5 | 8.5 | 7 | 6 | 7 | 7 |

| Extrudability | 4 | 5 | 7 | 7 | 9 | 10 | 8 | 8 |

| Finish - Mill | 5 | 5 | 7 | 7 | 8 | 9 | 10 | 7 |

| Finish - Bright | 4 | 4 | 5 | 5 | 7 | 8 | 10 | 4 |

| Finish - Dull (etch) | 10 | 10 | 8 | 8 | 8 | 7 | 4 | 4 |

| Electrical Conductivity | 6 | 6 | 7 | 7 | 8 | 8 | 8 | 10 |

| Weldability | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Corrosion Resistance | 8 | 8 | 9 | 9 | 10 | 10 | 9 | 10 |

|

Excellent/high = 10 - 9 (highly recommended) Above average = 8 Average = 7 - 6 Below average = 5 - 4 Low/poor = 3 - 1 (not recommended) |

MECHANICAL PROPERTIES

The following tables lists minimum yield strength, minimum ultimate tensile strength, and minimum elongation values. Yield strength, ultimate tensile strength, and elongation property values are determined with standard test method ASTM B557. This table also includes hardness screening criteria values, indicated in parentheses reference. As applicable, minimum electrical conductivity values are also specified.

METRIC

| Alloy & Temper | Specified Thickness1 (mm) Over Thru |

Minimum Yield Strength2 (Mpa) |

Minimum Ultimate Tensile Strength2 (Mpa) |

Minimum Elongation2 (%) |

Typical Hardness Values3 Rockwell E |

Minimum Electrical Conductivity4 % IACS |

|

| 1100-O | all | - | 20 | 75-105 | 25 | - | - |

| 1100-H112 | all | - | 20 | 75 | - | - | - |

| 1350-H111 | all | - | 25 | 60 | - | - | 61.0 |

| 3003-O | all | - | 35 | 95-130 | 25 | - | - |

| 3003-H112 | all | - | 35 | 95 | - | - | - |

| 3004-H112 | 6.30 | 12.50 | 60 | 160 | 7 | 45 | - |

| 6005-T1 | - | 12.50 | 105 | 170 | 16 | 54 | - |

| 6005-T5 | - | 3.20 | 240 | 260 | 8 | 90 | - |

| 6005A-T1 | - | 6.30 | 100 | 170 | 15 | 54 | - |

| 6005A-T61 | - | 6.30 | 240 | 260 | 8 | 90 | - |

| 6060-T61 | - | 3.20 | 170 | 205 | 8 | 60 | - |

| 6061-T4 | all | - | 110 | 180 | 16 | 62 | - |

| 6061-T6 | - | 6.30 | 240 | 260 | 8 | 89 | - |

| 6063-T1 | - | 12.50 | 60 | 115 | 12 | 37 | - |

| 6063-T4 | - | 12.50 | 70 | 130 | 14 | 41 | - |

| 6063-T5 | - | 12.50 | 110 | 150 | 8 | 55 | - |

| 6063-T52 | - | 25.00 | 110-170 | 150-205 | 8 | 54 | - |

| 6063-T6 | - | 3.20 | 170 | 205 | 8 | 70 | - |

| 6066-T6 | all | - | 310 | 345 | 8 | 96 | - |

| 6070-T6 | - | 80.00 | 310 | 330 | 6 | 91 | - |

| 6082-T6 | 5.00 | 20.00 | 260 | 310 | 6 | 90 | - |

| 6101-H111 | 6.30 | 50.00 | 55 | 85 | - | - | 59.0 |

| 6101-T6 | 3.20 | 12.50 | 170 | 200 | - | 70 | 55.0 |

| 6101-T61 | 3.20 | 18.00 | 105 | 140 | - | 60 | 57.0 |

| 6101-T63 | 3.20 | 25.00 | 150 | 185 | - | 70 | 56.0 |

| 6101-T64 | 3.20 | 25.00 | 55 | 105 | - | 46 | 59.5 |

| 6101-T65 | 3.20 | 20.00 | 140-185 | 170-220 | - | 60 | 56.5 |

| 6105-T1 | - | 12.50 | 105 | 170 | 16 | 54 | - |

| 6105-T5 | - | 12.50 | 240 | 260 | 8 | 90 | - |

| 6351-T4 | - | 20.00 | 130 | 220 | 8 | 64 | - |

| 6351-T6 | - | 3.20 | 255 | 290 | 8 | 91 | - |

| 6463-T1 | - | 12.50 | 60 | 115 | 12 | 31 | - |

| 6463-T5 | - | 12.50 | 110 | 150 | 8 | 55 | - |

| 6463-T6 | - | 3.20 | 170 | 205 | 8 | 60 | - |

| 7004-T5 | - | 38.00 | 315 | 370 | 10 | 95 | - |

| 7005-T53 | - | 20.00 | 305 | 345 | 10 | 95 | - |

| 7129-T5 | - | 12.50 | 340 | 380 | 9 | 100 | - |

| 7129-T6 | - | 12.50 | 340 | 380 | 9 | 100 | - |

Imperial

| Alloy & Temper | Specified thickness1 (in) Over Thru |

Minimum Yield Strength2 (ksi) |

Minimum Tensile Strength2 (ksi) |

Minimum Elongation2 (%) |

Typical Hardness Values3 Rockwell E |

Minimum Electrical Conductivity4 % IACS |

|

| 1100-O | all | - | 3.0 | 11.0-15.5 | 25 | - | - |

| 1100-H112 | all | - | 3.0 | 11.0 | - | - | - |

| 1350-H111 | all | - | 3.5 | 8.5 | - | - | 61.0 |

| 3003-O | all | - | 5.0 | 14.0-19.0 | 25 | - | - |

| 3003-H112 | all | - | 5.0 | 14.0 | - | - | - |

| 3004-H112 | 0.250 | 3.000 | 9.0 | 23.0 | 7 | 45 | - |

| 6005-T1 | - | 0.500 | 15 | 25 | 16 | 54 | - |

| 6005-T5 | - | 0.124 | 35 | 38 | 8 | 90 | - |

| 6005A-T1 | - | 0.249 | 14.5 | 25.0 | 15 | 54 | - |

| 6005A-T61 | - | 0.249 | 35.0 | 38.0 | 8 | 90 | - |

| 6060-T61 | - | 0.124 | 25.0 | 30.0 | 8 | 60 | - |

| 6061-T4 | all | - | 16.0 | 26.0 | 16 | 62 | - |

| 6061-T6 | - | 0.249 | 35.0 | 38.0 | 8 | 89 | - |

| 6063-T1 | - | 0.500 | 9.0 | 17.0 | 12 | 37 | - |

| 6063-T4 | - | 0.500 | 10.0 | 19.0 | 14 | 41 | - |

| 6063-T5 | - | 5.00 | 16.0 | 22.0 | 8 | 55 | - |

| 6063-T52 | - | 1.000 | 16.0-25.0 | 22.0-30.0 | 8 | 54 | - |

| 6063-T6 | - | 0.124 | 25.0 | 30.0 | 8 | 70 | - |

| 6066-T6 | all | - | 45.0 | 50.0 | 8 | 96 | - |

| 6070-T6 | - | 2.999 | 45.0 | 48.0 | 6 | 91 | - |

| 6082-T6 | 0.200 | 0.750 | 38.0 | 45.0 | 6 | 90 | - |

| 6101-H111 | 0.250 | 2.000 | 8.0 | 12.0 | - | - | 59.0 |

| 6101-T6 | 0.125 | 0.500 | 25.0 | 29.0 | - | 70 | 55.0 |

| 6101-T61 | 0.125 | 0.749 | 15.0 | 20.0 | - | 60 | 57.0 |

| 6101-T63 | 0.125 | 1.000 | 22.0 | 27.0 | - | 70 | 56.0 |

| 6101-T64 | 0.125 | 1.000 | 8.0 | 15.0 | - | 46 | 59.5 |

| 6101-T65 | 0.125 | 0.749 | 20.0-27.0 | 25.0-32.0 | - | 60 | 56.5 |

| 6105-T1 | - | 0.500 | 15.0 | 25.0 | 16 | 54 | - |

| 6105-T5 | - | 0.500 | 35.0 | 38.0 | 8 | 90 | - |

| 6351-T4 | - | 0.749 | 19.0 | 32.0 | 8 | 64 | - |

| 6351-T6 | - | 0.124 | 37.0 | 42.0 | 8 | 91 | - |

| 6463-T1 | - | 0.500 | 9.0 | 17.0 | 12 | 31 | - |

| 6463-T5 | - | 0.500 | 16.0 | 22.0 | 8 | 55 | - |

| 6463-T6 | - | 0.124 | 25.0 | 30.0 | 8 | 60 | - |

| 7004-T5 | - | 1.499 | 46.0 | 54.0 | 10 | 95 | - |

| 7005-T53 | - | 0.750 | 44.0 | 50.0 | 10 | 95 | - |

| 7129-T5 | - | 0.500 | 49.0 | 55.0 | 9 | 100 | - |

| 7129-T6 | - | 0.500 | 49.0 | 55.0 | 9 | 100 | - |

FOOTNOTES FOR MECHANICAL PROPERTIES 1 the thickness of the cross section from which the tensile test specimen is taken determines the applicable mechanical properties. 2 these values may vary with thickness. Refer to the current issue of the aluminum standards and data. 3 typical hardness values are for reference only. 4 % IACS at 20°C (68°F) – International Annealed Copper Standard.